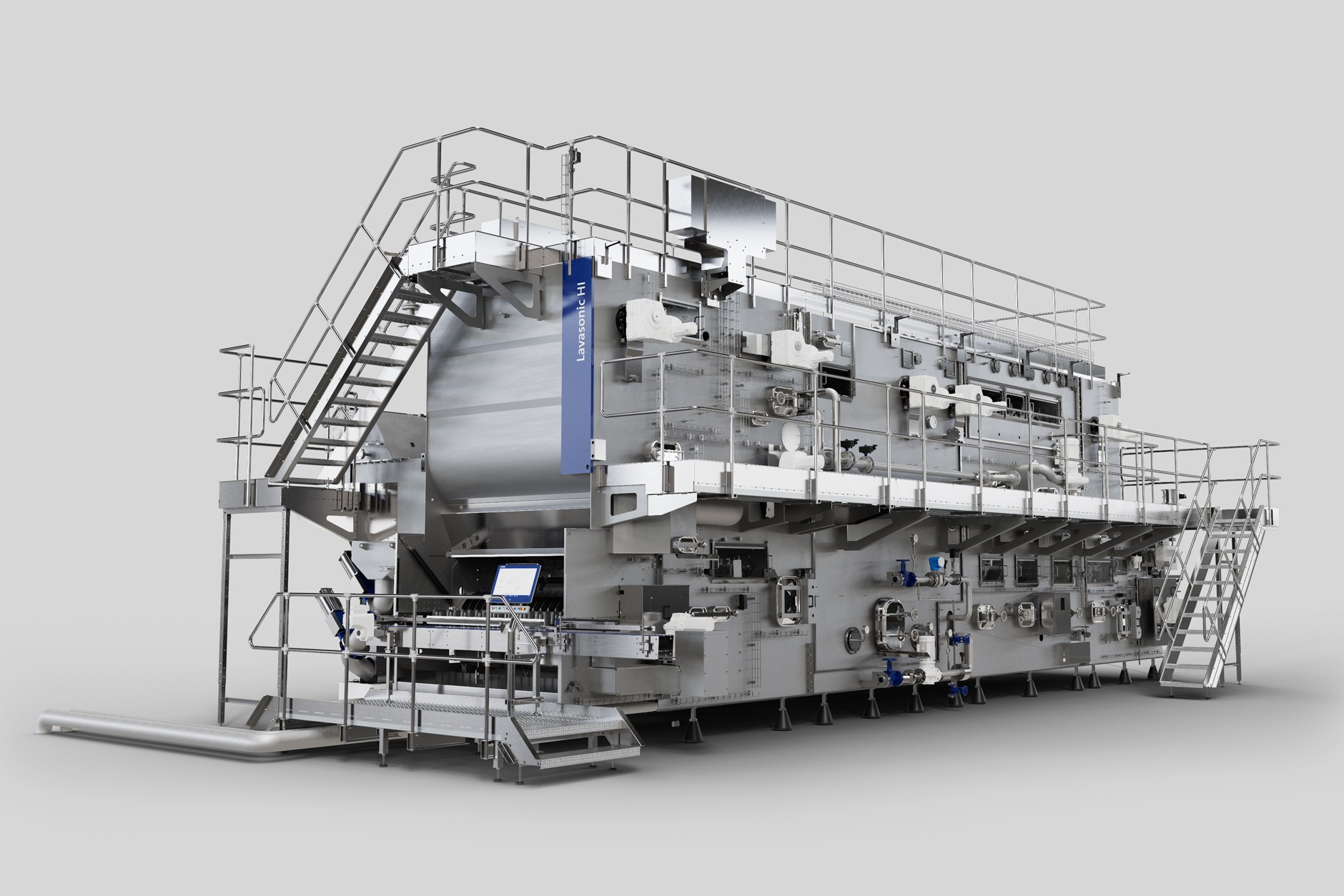

The new generation of bottle washers

- The Lavasonic HI boosts efficiency, sustainability and flexibility

- Efficient cleaning, thanks to ultrasound technology and high-intensity module

- Reduces treatment times by up to 40 per cent, the energy needed by 30 per cent, fresh water consumption by 20 per cent and the carbon footprint by 35 per cent

- Gentle transport through the machine, thanks to integrated bottle fastening system

Bottle washing is one of the key constituents of every returnable-glass line, in regard to both hygiene and energy consumption. Tried-and-tested processes scoring highly in terms of robust engineering and reliable results have become established practice over decades. But the machines currently in use need a lot of space, which renders their integration into modern, space-optimised line concepts rather difficult. At the same time, requirements for resource efficiency, flexibility and process reliability have been increasing steadily: Empties with varying degrees of soiling, rising energy prices and the wish to achieve sustainability in production pose ever new challenges for today’s cleaning technology.

Krones’ targeted response to these trends is the Lavasonic HI. This new generation of bottle washers combines proven principles with innovative approaches in order to boost efficiency, flexibility and sustainability.

Purposefully deployed ultrasound technology

The pretreatment section features an ultrasound zone, which uses focused cavitation – that is, the generation and implosive collapse of microscopic vapour bubbles within the cleaning medium – to effectively dislodge dirt and label material. It makes for enhanced diffusion of the cleaning medium and shorter detachment times while also reducing the amount of particles (especially ink particles) carried into the caustic. At the same time, it cuts consumption of chemical cleaning agents and extends the intervals between replacement of the caustic.

New treatment technology for even greater flexibility

The Lavasonic HI includes an additional treatment unit: the high-intesity module, which is an integral part of the bottle washing process and ensures especially effective removal of residues. Thanks to its flexible control options, the module can be optimally matched to different input materials – a crucial advantage when ever-changing requirements have to be met in the production process.

Innovative fastening system for gentle transport of glass bottles

Another design innovation is an integrated system for securely holding the containers in place, which ensures optimum flow routing for spraying the bottles’ exterior and for perfectly cleaning their inside as well – especially with relatively high jetting pressures. At the same time, it makes for particularly gentle container transport through the machine, thus substantially reducing mechanical stress on lightweight glass bottles, in particular. The fastening system is also instrumental in achieving a higher number of bottle use cycles, which significantly boosts both resource-economy and sustainability in the returnable-container system.

Quantifiable resource-economy

But the new bottle washer scores highly not only with its innovative technical concept but also with the tangible benefits it provides in ongoing operation. For example, treatment times can be reduced by up to 40 per cent and the thermal energy needed by up to 30 per cent while fresh water consumption can be cut by up to 20 per cent. At the same time, it is possible to downsize the carbon footprint by up to 35 per cent and mechanical stress on the bottles by up to 50 per cent – a substantial reduction that considerably helps ensure gentle handling, especially for sensitive lightweight glass bottles. On request, a fresh-water jetting system in clean design can be integrated that offers additional microbiological safety and significantly reduces the maintenance outlay involved. A further advantage lies in the well-thought-out arrangement of the circulation pumps in the caustic. Thanks to their horizontal position, it is considerably easier to access them for maintenance work.

Digital functions

Equipped with the latest touchscreen technology and state-of-the-art programmable logic control (PLC), our machines are in the best possible shape to cope with any requirement the digital future may bring.

The Lavasonic HI provides variable and adaptable cleaning performance supported by digitally controlled cleaning programs. The advanced touchscreen interface enables operators to quickly and easily choose from the range available a program suitable for handling the degree of soiling involved. Without any time delay, the operator specifies the key factors determinant for the cleaning process, such as ultrasound performance, HI module control and flow routing, in dependence on the requirements posed by the current situation.

About Krones

The technology company Krones headquartered in Neutraubling, Germany, is a global leader in developing and manufacturing state-of-the-art machines and complete lines for the fields of process, filling and packaging technology. Its portfolio is perfectly complemented by additional products and services provided by the Krones subsidiaries, such as solutions for anything to do with digital transformation, intralogistics and plastics recycling. Krones employs more than 20,000 people worldwide. Consolidated sales in 2024 totalled 5.3 billion euros. The Krones Group includes not only Krones AG (listed on the stock exchange), but also more than 100 subsidiaries and further production, sales and service companies worldwide.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl