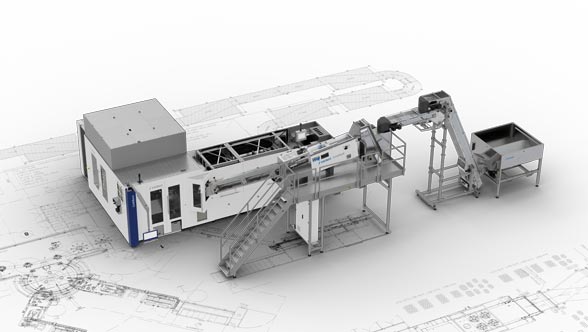

The revolutionary line concept

Our new Ingeniq line generation provides answers to the most frequently asked customer questions and requirements and is the realisation of a Krones vision that was already outlined at the drinktec 2022: Low total operating costs with a consistently high efficiency.

The concept consists of modular and standardised components that utilise robotics and artificial intelligence – highly efficient state-of-the art machines. At the same time, its sophisticated design reduces the overall complexity of the line layout.

Ingeniq – the line itself

Our new digital automation architecture enables highly efficient individual machines to be networked together in a line to generate the greatest possible automation: from preform in-house manufacturing through the high-speed bottling of still water with the ErgoBloc L to the autonomous supply of materials and intelligent packaging systems – always with a close eye on production.

This is what distinguishes Hydronomic as part of Ingeniq

- Minimised quantity of waste water thanks to its sophisticated technology

- It offers the best possible access for operators and service personnel

- Reduces water consumption thanks to fully automatic control of all relevant process parameters

This is what distinguishes VarioClean as part of Ingeniq

- Excellent cleaning result via controlling the cleaning processes according to conductivity, temperature, and time

- Minimised loss of media and waste water via automatic processes

- Permanent target/set-point value comparison and automatic correction

- Configurable time preselection for starting cleaning programs

This is what distinguishes ErgoBloc L as part of Ingeniq

- Connected to an autonomous material supply and container discharge system

- Modulfill Dual with adjacent product tank

- Single-arm grippers as a new neck-handling system

This is what distinguishes Contifeed as part of Ingeniq

- Special design of feed rail: suitable for very light preforms and high output ranges

- Additional P.E. sensor in the feed rail for optimum preform flow

This is what distinguishes Contiform as part of Ingeniq

- Automatic rejection of preforms and empty containers

- FlexWave: Microwave technology for preform heating

- Gripper head with overload clutch and optimised P.E. sensors

- Contiloop AI: Automatic process control

This is what distinguishes PET-View as part of Ingeniq

- Advanced camera systems and sensors enable the best possible control of preforms and blown bottles

- Continuous inline measurement of preform moisture and temperature as well as the wall thickness distribution of the blown bottle ensure consistent product quality

This is what distinguishes Ergomodul as part of Ingeniq

- Equipped with two Contiroll TS labelling stations

- Including glue vapour extraction system, which significantly extends cleaning intervals

- Partial production to reduce the rejection rate

- Including Checkmat for label inspection

- Works with a robot cell for automatic label supply:

- AGVs fill the robot cell with pallets loaded with labels.

- A robot prepares the gluing process, reloads the label reels and splices the reel ends at full speed.

This is what distinguishes Modulfill Dual as part of Ingeniq

- Adjacent product tank

- New neck-handling system

- Connected to an autonomous preform and container discharge system

This is what distinguishes Checkmat Compact as part of Ingeniq

- Compact, centralised unit

- Optional: integrated coding/dating device (laser/inkjet)

- Automatic guide rail adjustment

- Optional: Automatic adjustment of the inspection unit height

- Cap inspection unit:

- 360° inspection without blind spots – also suitable for tethered caps

- Optional accuracy inspection of caps from above

- Optional software expansions: Rotation angle monitoring with AI and inkjet imprint inspection

- Fill level inspection:

- Using a camera

- Optional: with AI for simplified set-up and greater flexibility

This is what distinguishes Ozonomic as part of Ingeniq

- Ideally designed to suit adjacent Krones technologies: Water treatment systems from the Hydronomic series and fillers from the Modulfill range

- Ensures maximum microbiological safety for product, container and cap

Special features within Ingeniq lines for non-returnable containers*

- Container infeed: camera-supported monitoring of the infeed lanes

- Packing module:

- Universally applicable push rods and film folders, to reduce change-over parts and times

- Detection of handling parts using RFID for increased process reliability

- Connection to autonomous material supply using AGV for film reels, carton blanks and LitePac Top Clips

- Insertion robot for feeding the lift magazine with wraparound and tray blanks

* Depending on the version of the Variopac Pro

Special features within Ingeniq lines for non-returnable containers*

- Shrinking tunnel: automatically adjustable with up to 20 percent reduced energy consumption

- Camera-assisted machine observation and guided troubleshooting

* Depending on the version of the Variopac Pro

Special features within Ingeniq lines for non-returnable containers

Robobox T-GS

- Collision detection: pack-specific diagnostics of values exceeding the torque in the tripod servo motors to detect gripping tool losses

- Infeed Pro: Pack feed with innovative, self-retightening chain tensioner, intelligent sensor technology for maximum process reliability and optimum operator accessibility

- Intelligent torque monitoring with automatic ideal value formation to precisely and early detect deviations in the layer formed

Special features within Ingeniq lines for non-returnable containers

Modulpal Pro

- Shutter gripper head: Redesigned segment rods with greater material thickness for reinforcement and stabilisation during layer transfer

- Camera-assisted machine observation and guided troubleshooting

Get to know Ingeniq – start here

Ingeniq – the digital access

Digitally networking the existing machines or line requires the so-called "Connect and Secure" connect-hardware, which provides access to the digital production world. That makes the existing line part of the digital world of Krones – visible, networked and able to be maintained remotely. With the Krones.world platform created, both customers and Krones have access to relevant production data at all times. The combination of digital tools, expertise and partnership-based cooperation makes it possible to reliably and securely achieve jointly defined performance promises.

Ingeniq – the alliance with the customer

An alliance stands for a partnership between individuals and/or organisations who pursue a common goal and both contribute to achieving this goal. The basis: Trust, reliability, and responsibility. With the Lifecycle Alliance for Ingeniq, Krones is entering precisely such a partnership with the customer. The goal: To achieve the agreed line efficiency together.

The line of the future

The new line concept of the future starts with bottling still water in PET containers – but that is just the beginning. Other container types and product categories will follow. With Ingeniq, Krones is transformed from a machine manufacturer into a comprehensive partner for production success in collaboration with the respective customer.