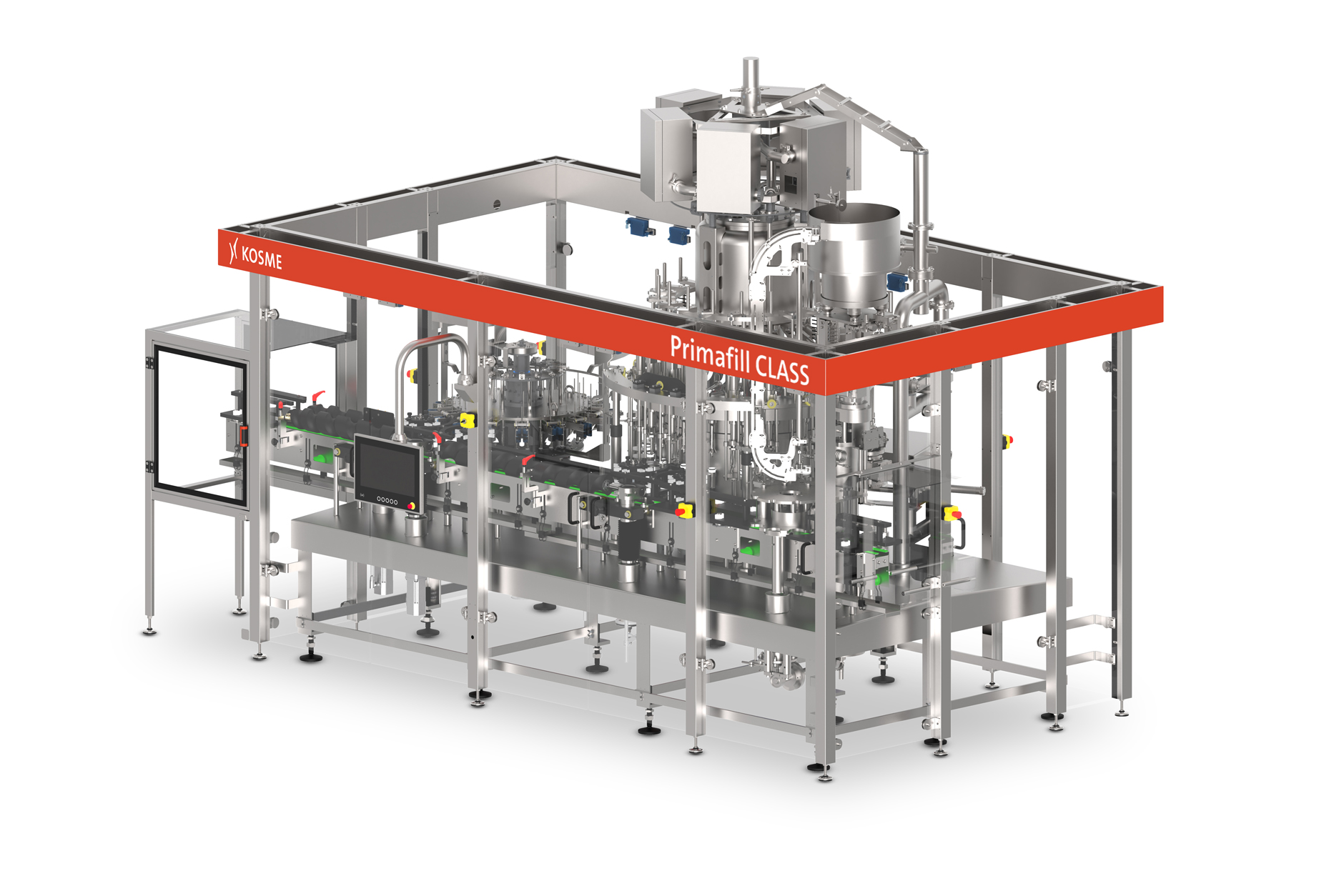

High-precision filling solution for the spirits industry

- The Primafill CLASS provides a particularly gentle filling process for spirits, featuring a low-pressure tank and electro-pneumatic nozzle control.

- Hygienic design with an automatic CIP system and external filling valves reduces the risk of contamination.

- The machine offers high-precision filling (±1 mm) and flexible adjustments to different bottle formats.

- Universal handling parts, conformity with ATEX safety standards and modular capping and corking systems make it both versatile and safe.

With the Primafill CLASS, Kosme is presenting a new generation of filling machines that have been developed specifically to meet the needs of the spirits industry. The system is designed for manufacturers who prioritise product integrity, hygiene, filling precision, and operational flexibility.

The Primafill CLASS preserves the characteristics of sensitive spirits through an electro-pneumatic nozzle control system that prevents backflow and minimises product and alcohol losses. A low-pressure tank ensures gentle product handling – making it ideal for both artisanal and industrially produced spirits.

Hygienic design

The machine meets the most exacting hygiene standards: Sloping surfaces prevent pooling of liquids, an automatic CIP (clean-in-place) system reduces manual cleaning procedures, and the external positioning of the filling valves minimises contamination risks. Additional safety features such as foam-cleanable capping heads and double seals increase microbiological safety.

A two-stage filling system prevents foaming, while the self-adjusting technology ensures a filling accuracy of ±1 mm. The automatic fill-level adjustment over a range of 65 mm enables flexible change-overs. Separate air- and product-return chambers ensure total separation and consistent quality.

Versatility

Universal starwheels and feed worms make for quick change-overs to different bottle sizes. The modular capping system supports a variety of closure types, including aluminium screw caps and T-top corks (also known as T-caps). The machine is suitable for handling both glass and PET bottles.

The Primafill CLASS is ATEX-certified to zone 0, meaning that it meets the EU’s safety standards for use in environments where combustive gases, vapours or dust are constantly present. It is also equipped with an integrated vapour extraction system. With its compact footprint and automated change-overs, it provides an efficient solution for modern production environments.

About Krones

The technology company Krones, headquartered in Neutraubling, Germany, is a leading international developer and manufacturer of state-of-the-art machines and complete lines for the areas of process, filling, and packaging technology. Additional products and services from Krones' subsidiaries, such as those relating to digitalization, intralogistics and recycling, complement the product portfolio. Krones employs more than 20,000 people worldwide. Sales in 2024 amounted to EUR 5.3 billion. In addition to the listed Krones AG, the Krones Group includes more than 100 subsidiaries and locations worldwide.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl