A new approach to packing and unpacking

Experience and innovation in packing and unpacking

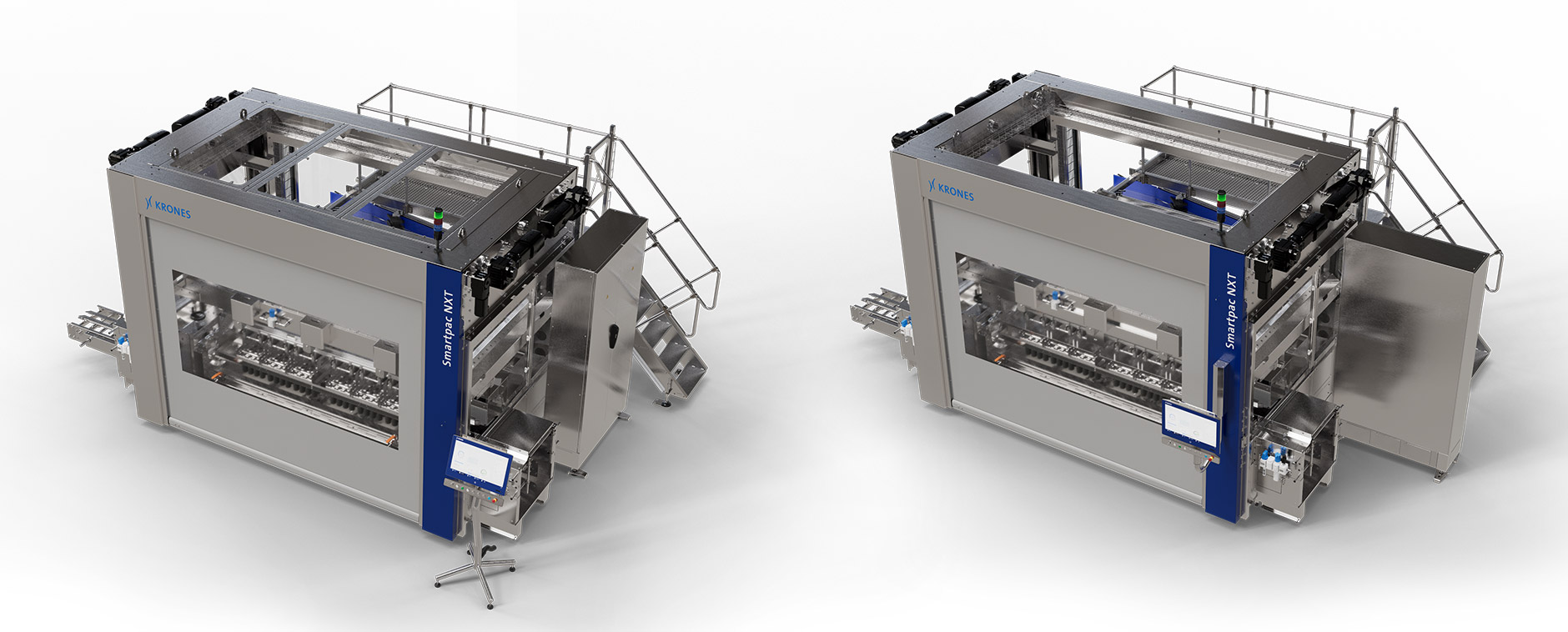

A wide variety of containers and packs is not uncommon these days. The task of the Smartpac NXT is to efficiently and gently pack and unpack various container formats into different secondary packaging. With its modular design and large range of gripper heads, this intermittent packer is best prepared for a wide spectrum of variants. Precisely coordinated movement sequences ensure gentle handling of your products - so your containers are in the best hands with the Smartpac NXT.

At a glance

- Intermittent packer for packing or unpacking different container types (cylindrical or specially-shaped containers made of glass or plastic) into different secondary packaging (crates, trays, cartons)

- Block length 1,400 to 2,900

- Machine frame in compact design

*All illustrations are with optional accessorie

Layout variants

Method of operation, features and additional equipment

Packing |

Unpacking |

Packing movement |

|

|

|

Transparent plastic panel

instead of metal grids

(with the H table variant; optional)

Second roller door

for increased accessibility to the back side of the machine

(with the H table variant; optional)

Integrated machine cover

for low-noise operation (optional)

Platform with stairs

(with the packer T table; optional)

Control cabinet

coupling;

lengthwise position

Connected HMI

stand-alone

Handling parts change-over

coupling by means of crank or motorised

Control cabinet

stand-alone;

Connected HMI

attached

Driving force in the topic of digitalization

- HMI-guided change to troubleshooting

- Advanced Analytics

- Integrated Analytics

- Shopfloor Guidance

- Monitoring of drive data

- Display of data via mobile end devices possible

This is why the Smartpac NXT is enviro-certified

- Servo-controlled main drives

- Energy recovery via the modular B&R ACOPOSmulti drive system

- Omission of pneumatic drives to the greatest extent possible

- Use of enclosed lifetime-lubricated bearings

- Employment of enviro-compliant H1 lubrication grease and oil

- enviro option: Energy measuring package

- Energetic advantages due to low moving mass

Benefits

Sophisticated design and superior engineering

With its stainless steel design, the Smartpac NXT not only looks good, but is also corrosion-resistant, robust and easy to clean. The innovative kinematics ensure reduced cycle times, high positioning accuracy and less moving mass, which has a positive effect on wear and maintenance costs.

Flexible application

The extremely diverse variants offer high flexibility when it comes to the gripping devices, meaning that the Smartpac NXT can handle a large number of different container and pack types.

Quick conversion

The Smartpac NXT is soon ready for action again after a product change-over. With its short change-over times and brief periods of inactivity, the packer is distinguished by its high productivity.

Compact design and good accessibility

Thanks to its compact design, integrated protection and good accessibility from all sides, the Smartpac NXT allows faults to be rectified quickly and easily, ensuring a high level of efficiency.

Clear operation

Production data, operating functions, status indicators, help texts and diagnostics tools in the respective native language make it possible to operate the equipment quickly and comfortably on the touch-screen on the Connected HMI.

Incredibly quiet

On request, the machine can be equipped with anintegrated machine cover for particularly quiet operation so that significantly less noise escapes to the outside compared to conventional packers.